During routine maintenance, an aluminum coil winding shaft was found with cracks. Customer’s technical department developed a repair procedure and after close cooperation with our engineering department the repair was carried out. The works carried were the following:

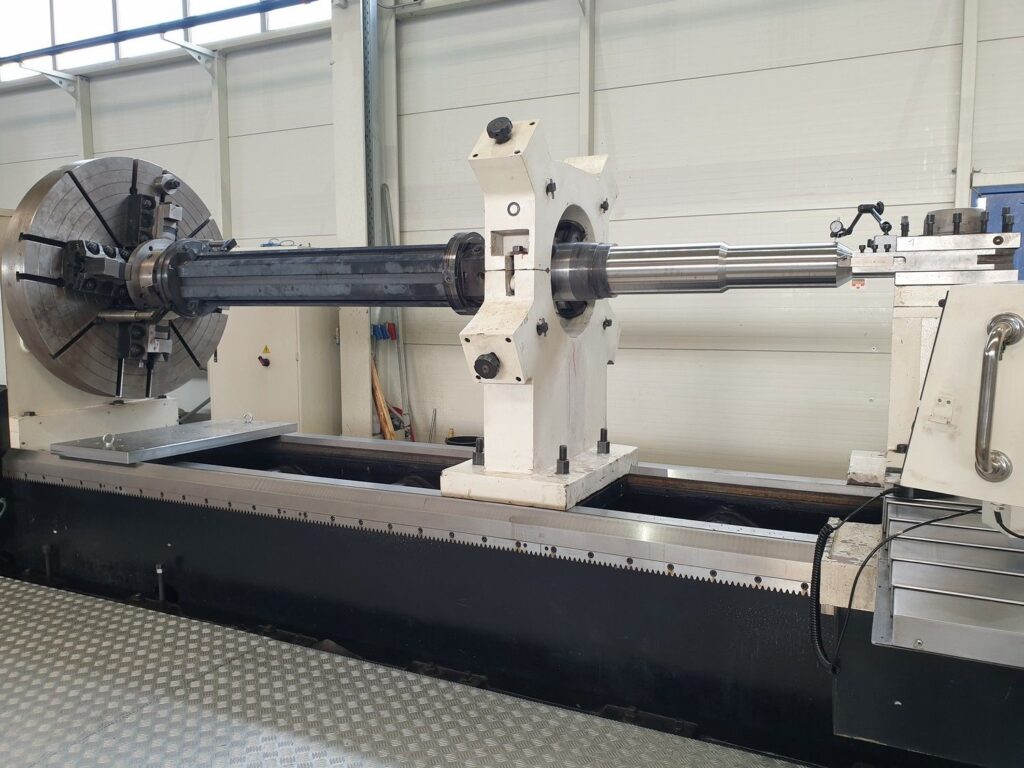

- Removal of shaft damaged section by machining on our CNC Heavy Duty Turning Lathe SK61168

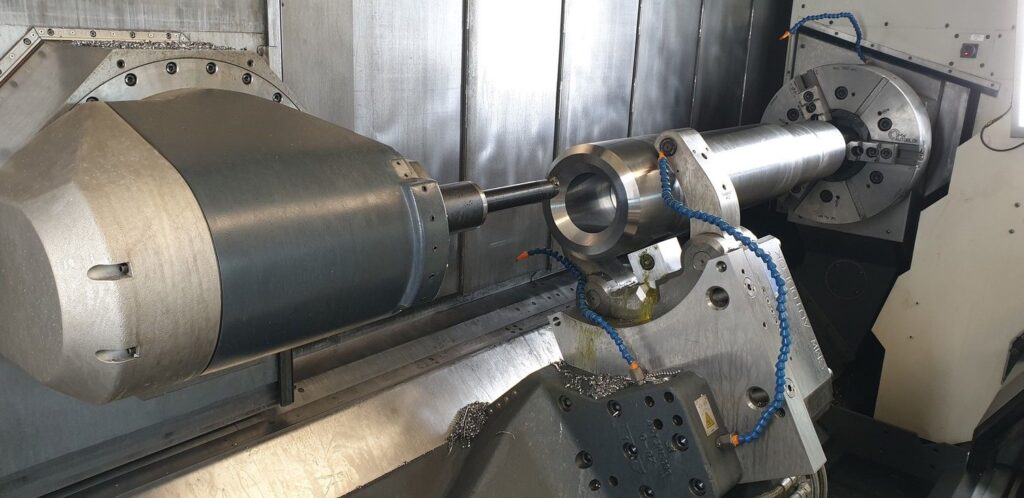

- Manufacturing of new hollow section on our 5axis Turning-Milling machine CTX3000 gamma TC, according to customers’ drawings and specifications

- Joining by TIG welding of the two sections on our FANUC Robotic TIG welding cell

- Final machining of the assembled and joined shaft on our CNC turning lathe SK61168