Mill roll chucks – bearing housings are amongst the most critical parts which are subjected to high loads.

Once the bore where the bearing is fitted, gets damaged the repair or replacement by new is inevitable. Repair can be done by machining the bore to oversize and fitting an equivalent bearing whereas replacement with new incur high costs.

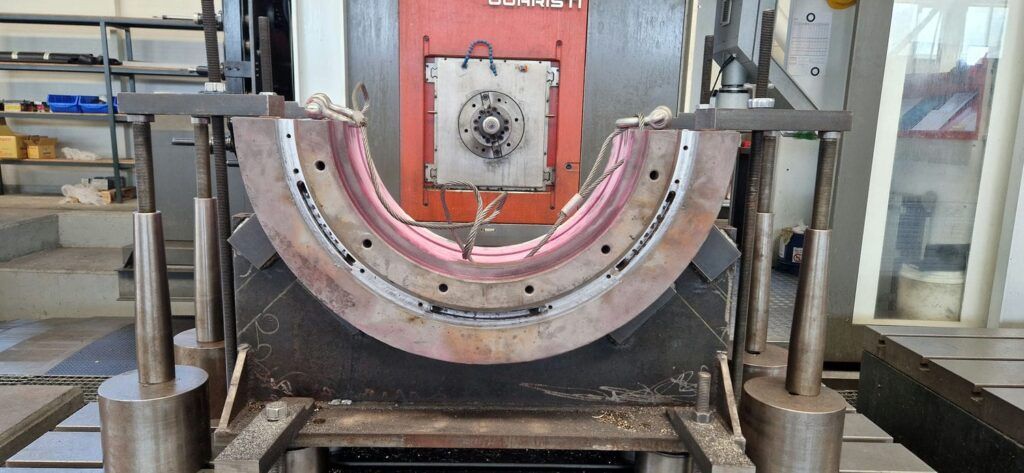

Laser cladding offers the advantage of restoring the bore back to initial dimensions fast, successfully and cost effectively. We have restored such roll chuks – bearing housings for our customer ELVAL who is amongst the top worldwide aluminum industries.

Briefly the process includes the machining on our CNC boring machine, of the damaged bore for preparation of the surface for Laser Cladding build-up, the entire bore surface built up and the final machining of the bore to final-initial dimensions and tolerances, again on our CNC boring machine.