During maintenance the gearbox was found with damage on the main input shaft, the upper bearing pocket at the cover plate and the bottom bearing pocket of the housing.

Extensive measurements and NDT inspections were carried out and a complete technical report send to customer before commencing of any works.

The main input shaft was inspected for runout and MPI was carried on the damaged journal. After rough machining, the journal was restored to original dimensions by Laser Cladding, followed by fine machining and grinding.

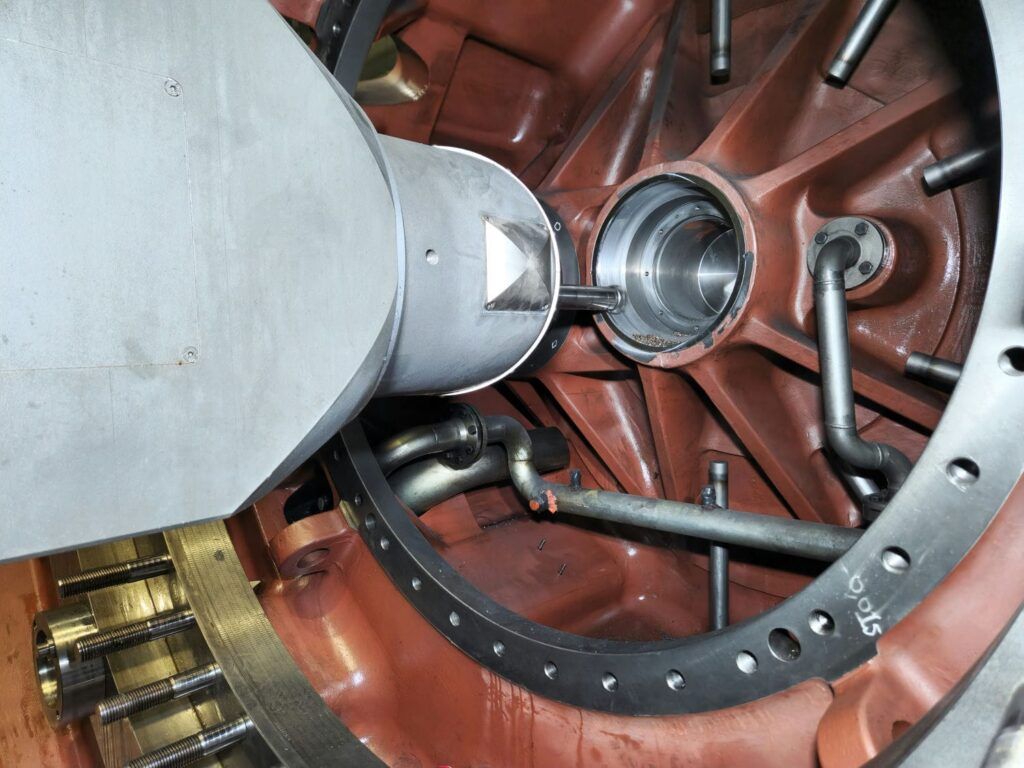

The upper bearing pocket on the cover plate was repaired by inserting a steel ring according Flender specialist who supervised the works. The cover plate pocket was first machined to oversize on our CNC boring machine, to install by liquid nitrogen a steel ring and after it was machined to final dimensions again on our CNC boring machine.

The same methodology was followed for the repair of the lower bearing pocket on the gearbox housing. The housing was first positioned and aligned on our CNC boring machine and after the pocket was machined to oversize for a steel ring to be fitted by liquid nitrogen. After final machining the restored pocket was ready to accommodate the new bearing.