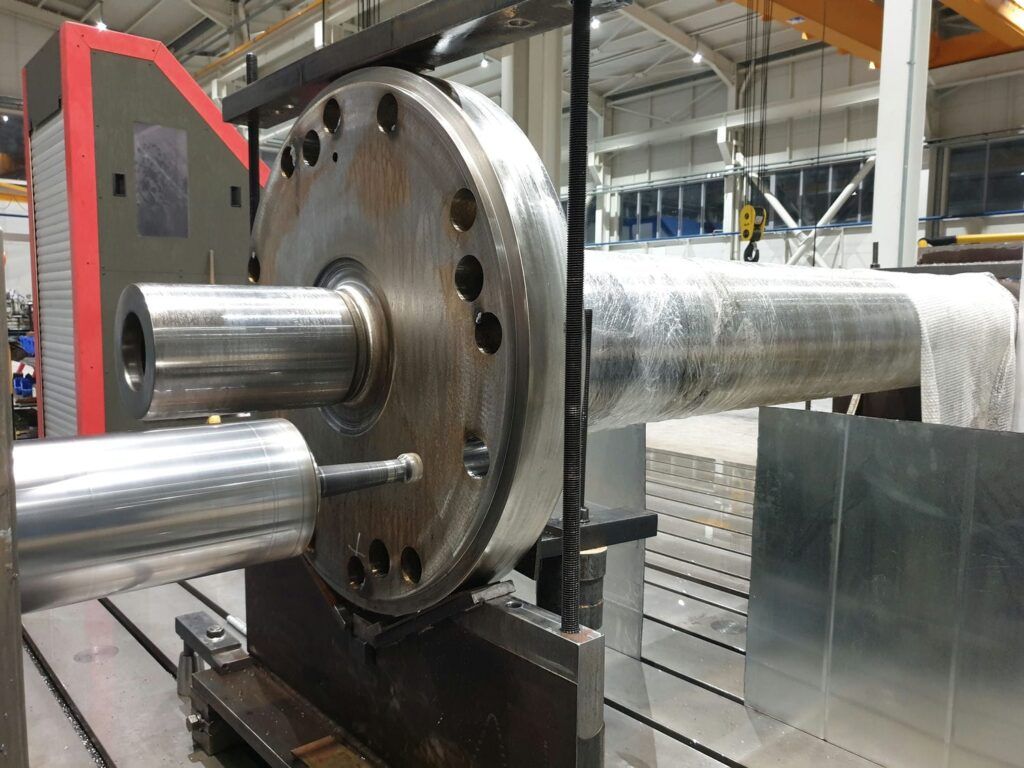

One of the two variable pitch propeller tails shafts of passenger ferry PREVELIS got bend after vessel grounding.

The tail shaft was removed and send to our workshop for repair. A section of more than 3 meters from the flange side was excessively bend. The biggest percentage of bend was removed by means of cold pressing and the rest by machining on a CNC turning lathe, thus restoring the straightness.

For restoring the former bend section to nominal dimensions, Laser Cladding was applied. More than 300kgs of steel powder were deposited in total along the shaft section and the flange.

After cooling, the Laser Cladded sections (shaft & flange) were stress relieved by means of ceramic pad heaters.

The final machining was carried out in two stages, first on our CNC turning lathe for restoring the shaft and flange diameters and second, on our CNC boring and milling machine where connecting bolt bores were restored as well as the hollow section through which the propeller pitch is controlled.